| Author |

Jiri Vitek, Martin Hudák, Michal Macuda, Simona Gasincova |

| Studio |

JVAW + Atelier3M + ICE Architects |

| Location |

Malá Morávka |

| Collaborating professions |

PW Atelier, Taros |

| Investor |

Ski areál Kopřivná |

| Supplier |

HSF , Hydrospol, ICE Coral3dcp |

| Date of completion / approval of the project |

March 2025 |

| Fotograf |

Alex Shoot Buildings |

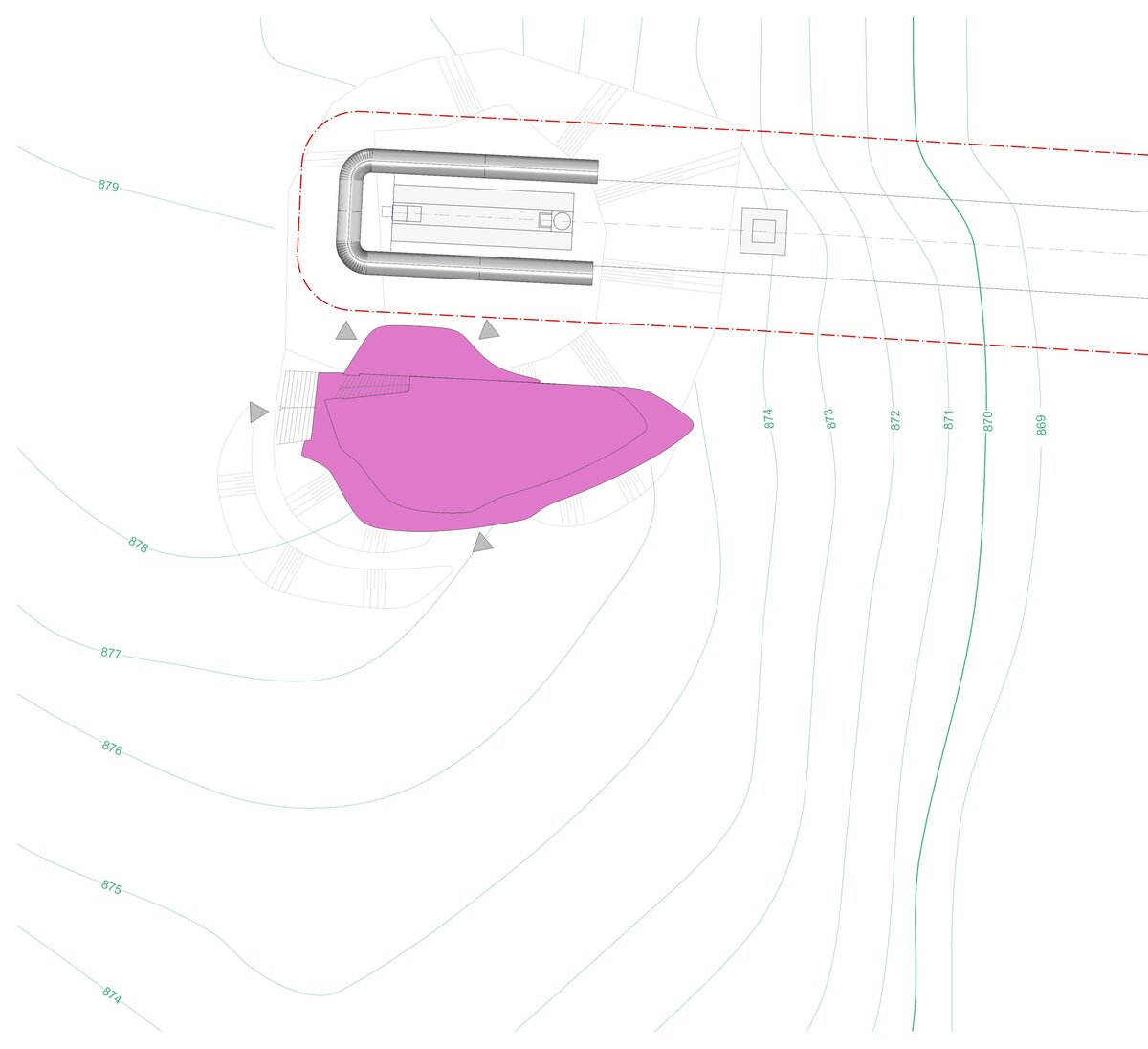

Enterprise is the name of the upper station of the cable car in Kopřivná – the first architectural project in the Czech Republic using large-format 3D concrete printing (3DCP) as part of a public building in a mountain environment. The sculptural form of the building, inspired by the raw geometry of the Jeseníky rock formations, was created as a technological prototype and at the same time a sensitive integration of architecture into the landscape.

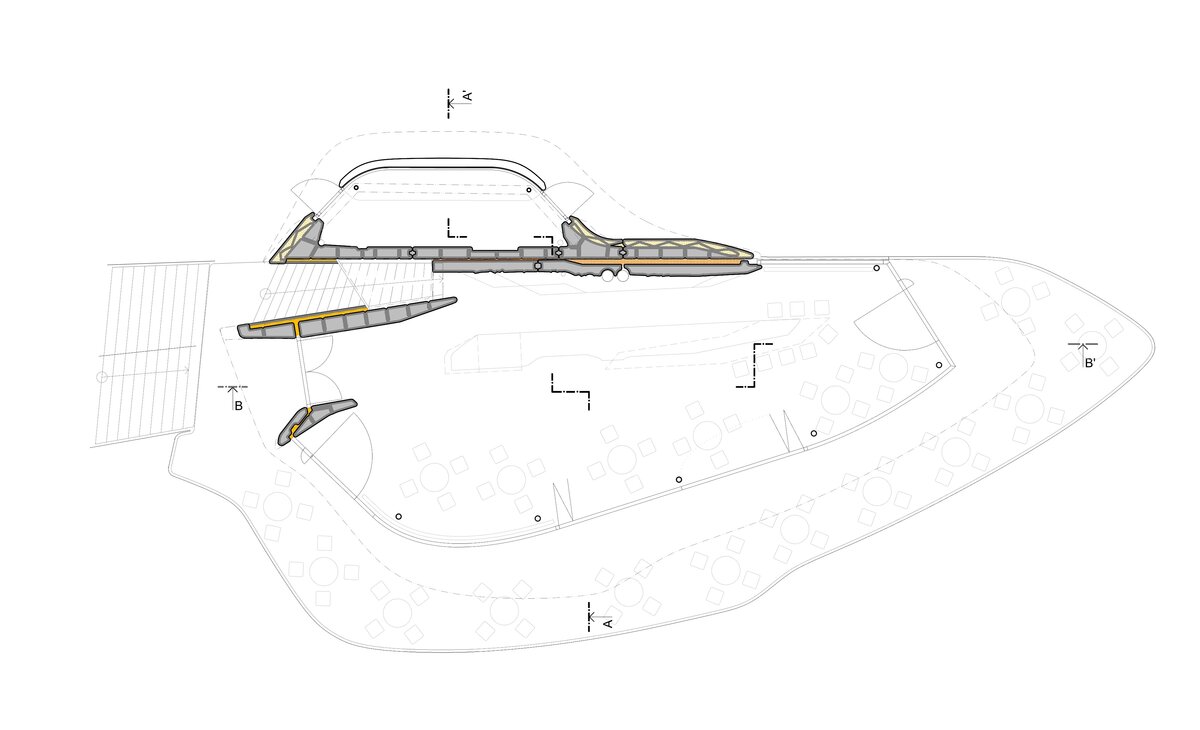

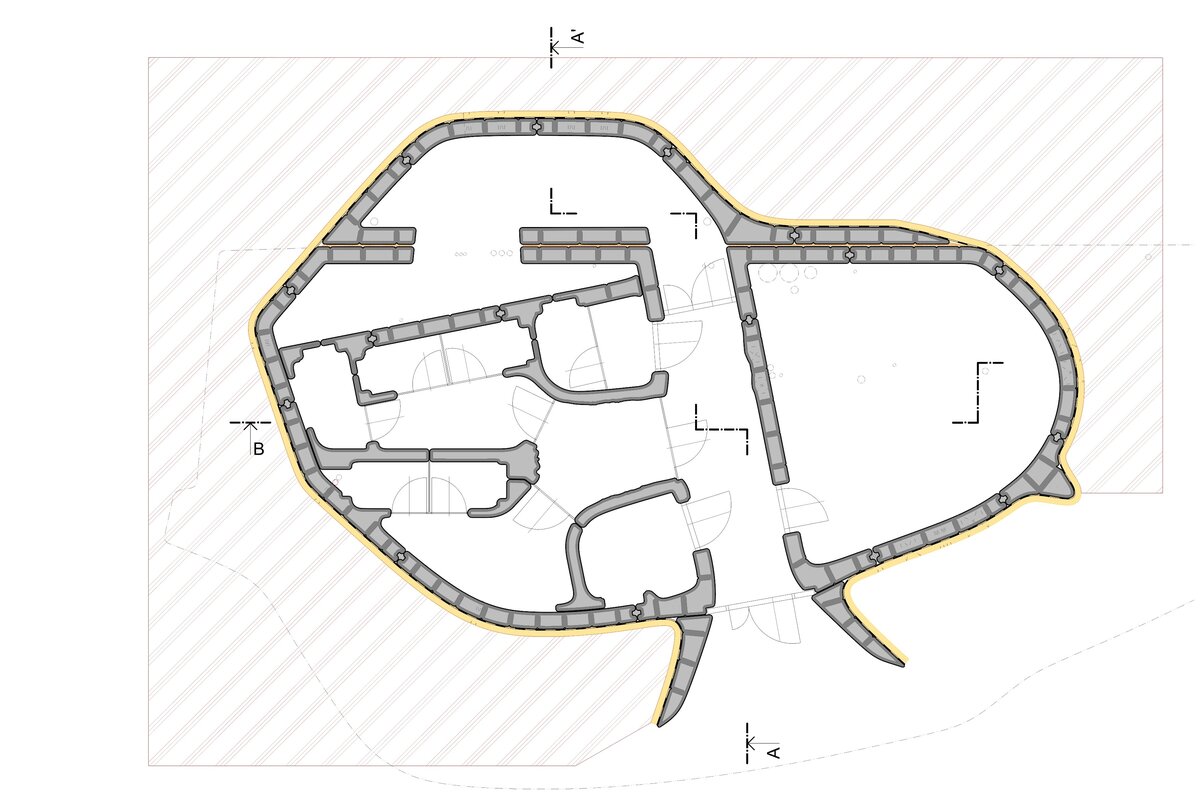

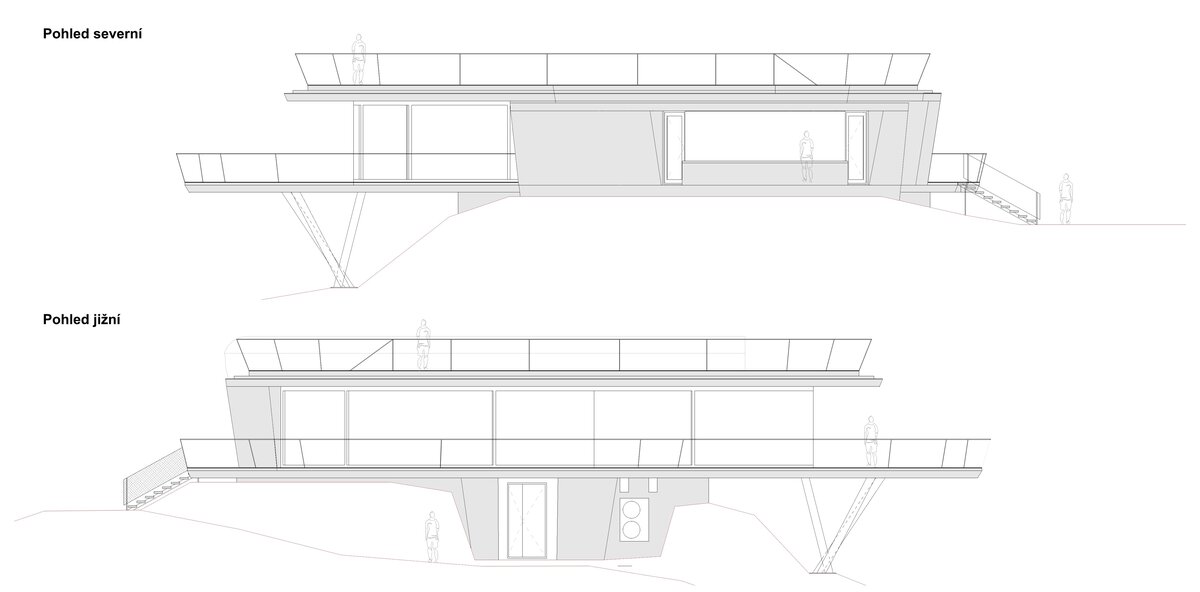

The building includes a control room for the cable car operation, an information center with a terrace, a green roof with a viewing platform and, at the lowest level, public toilets and storage facilities. The architectural solution connects printed concrete shells with integrated thermal insulation and landscaping that follow the surrounding landscape relief.

3DCP technology here represents not only a sustainable method of construction, but also becomes the language of architecture – it enables ergonomic shaping of mass, structural optimization and precise articulation or integration of other elements.

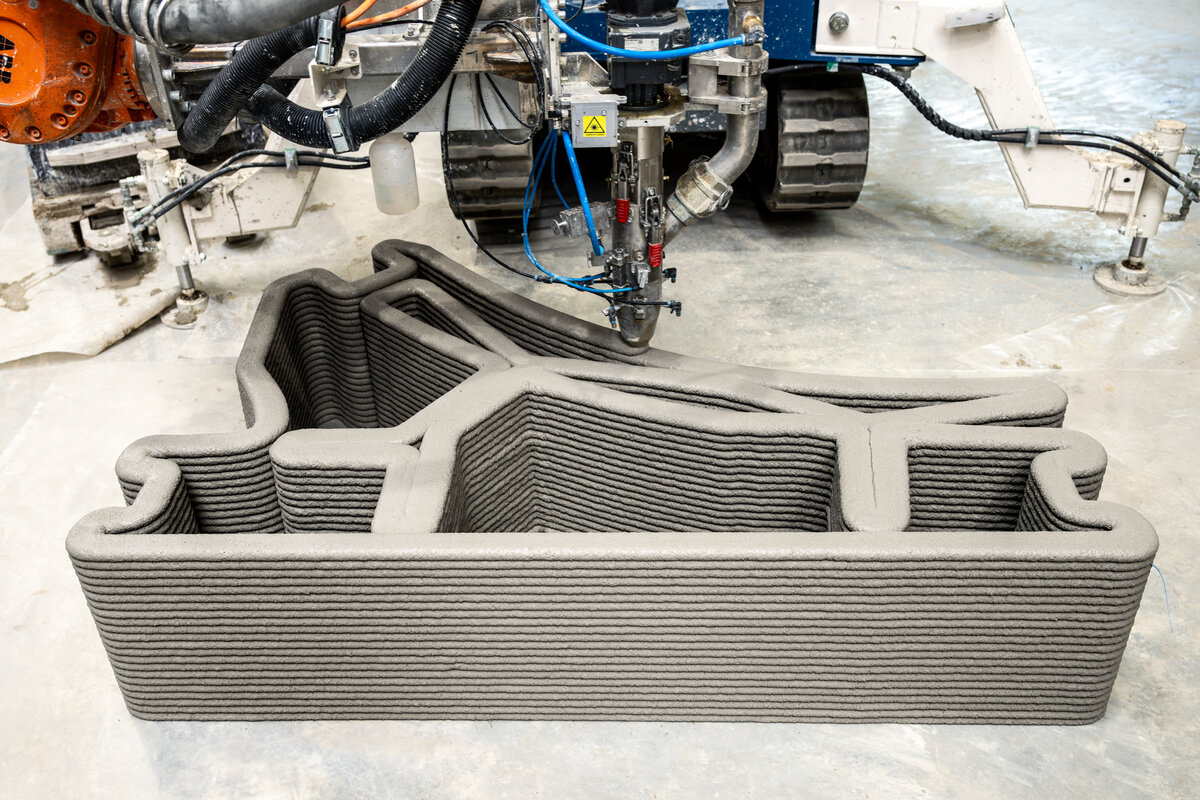

The dominant feature of the interior is the main information center desk, designed as a light printed lace that reflects the morphology of the surrounding landscape – ornament and tectonics are combined here into a single whole.

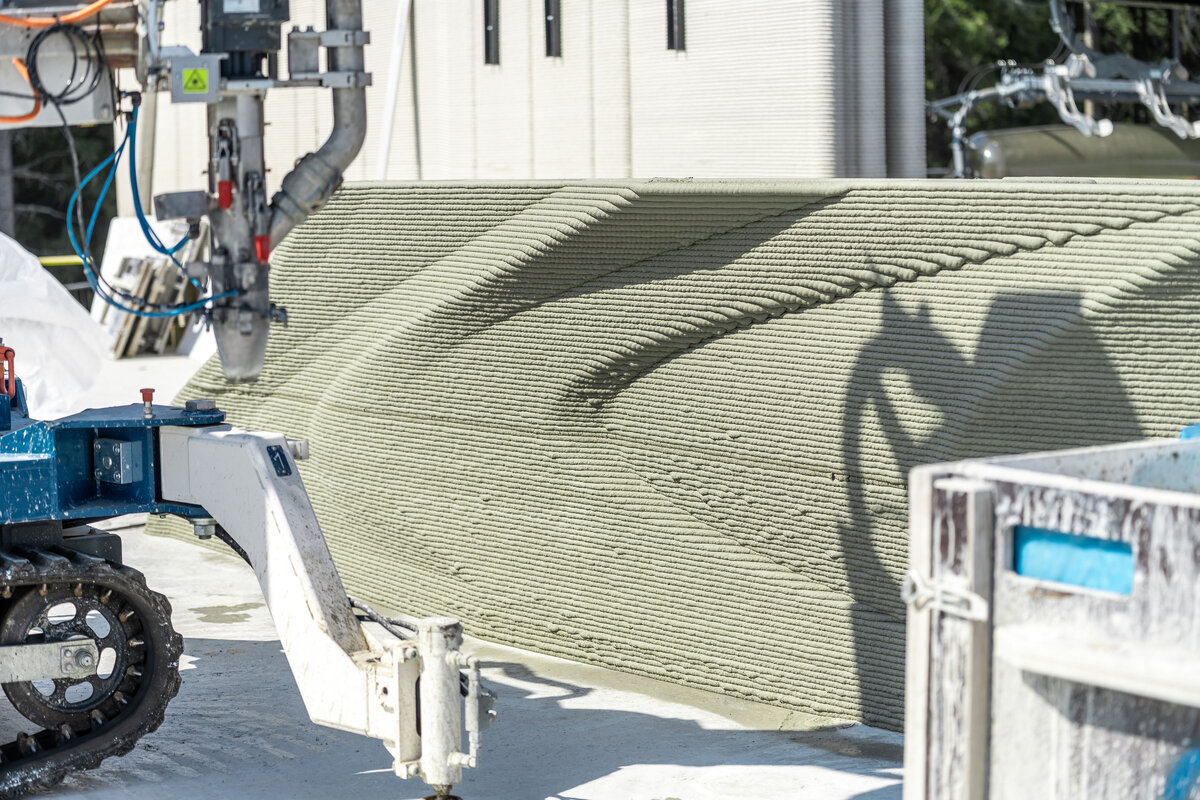

The project responded to the extremely demanding construction conditions, complicated terrain and the need to maintain the operation of the cable car throughout the construction period. The printing of the structural elements took place in the hall, while rapid assembly took place on site.

The control cabin was assembled on the foundation plate within one week, and three weeks after the foundation was laid, the cable car was put back into operation.

Enterprise is not just a technical object, but also a place for stopping, viewing and experiencing. It shows the possibility of how an experiment with material and form can be in balance with ecological consideration and landscape poetry.

Structural solution

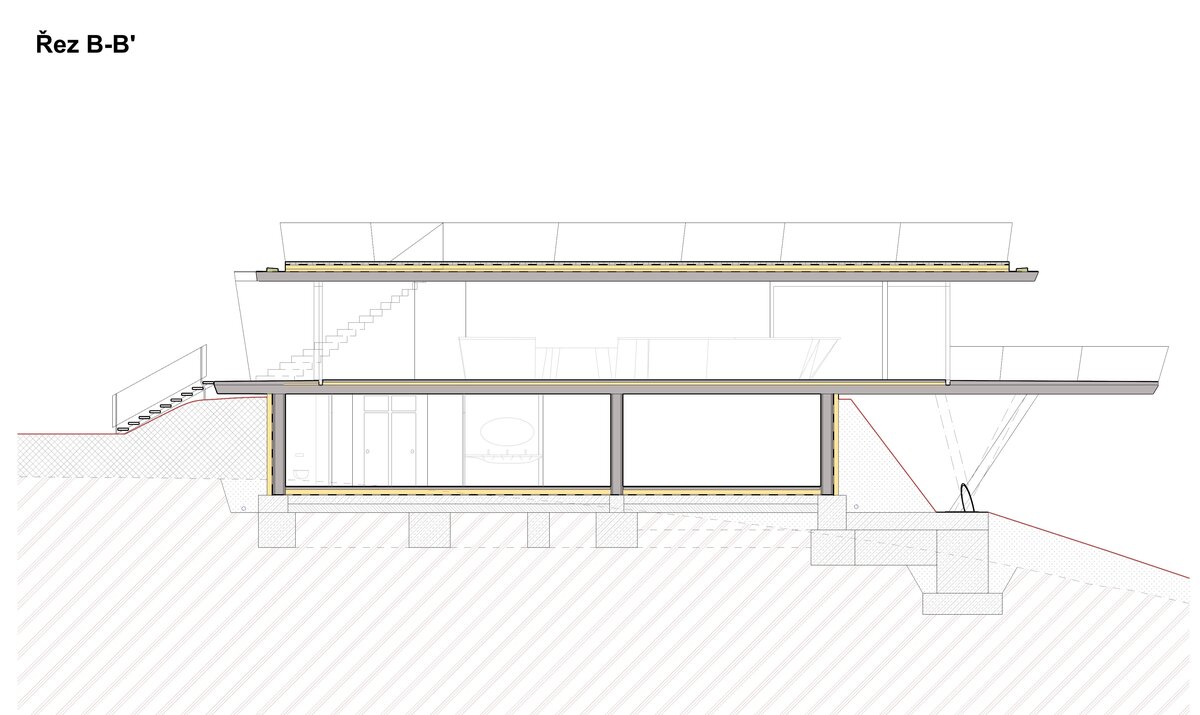

The foundation of the building is on bedrock. The structural system connects 3D printed, prefabricated, reinforced concrete parts and monolithic parts. The walls in the 1st PP are massive reinforced concrete t.l 250 mm, all vertical elements are made using 3DCP technology.

The cantilevered slabs – ceiling and roof – are supported on a combination of reinforced concrete 3D printed walls and steel columns. The largest consoles are supported by inclined steel tripods with footing foundations. The roofs have a slope optimized for the mountain climate, equipped with drainage systems and heating cables to prevent freezing.

All structures were assessed according to valid ČSN standards, PENB achieves the classification "very economical" (90 kWh/m².year). Acoustic separation was solved by a combination of heavy structures and a ventilated pre-mounted shell. Floor convectors are used to prevent condensation on large glass surfaces. A polyurethane screed with high resistance to moisture and frost is used throughout the building.

Production and installation

The concrete parts were printed in the hall. A total of 48+7 segments (walls, plinths, ceiling and roof elements of the cabin) were printed, each with a printing time of approximately 90–180 minutes, ceiling panels within 30 minutes. The material was optimized for natural loads (frost, moisture), with an admixture for higher cohesion of the layers. The concrete used corresponds to the strength class C30/37, supplemented with hardening accelerators and fiber reinforcement. The segments were designed for easy transport and handling - each segment was digitally checked before export to G-code. The printing technology uses a precise extruder with a ± 5mm tolerance.

The installation took place during the cable car shutdowns in four stages: foundation and relocation, prefabrication of the service, construction of the info center and finishing work (including heating, electrical, HVAC). Crane equipment was used, excavation and insulation work was coordinated with geotechnical supervision. The walkable roof is equipped with a railing made of a cable system and drainage layers to retain rainwater. The building is equipped with DUPLEX 1500/1100 heat recovery units, the air conditioning is admitted or led in the floors. The primary source of heat is an air-water heating unit with an accumulation tank and underfloor heating. All internal installations were carried out without cutting into the concrete wall

Green building

Environmental certification

| Type and level of certificate |

-

|

Water management

| Is rainwater used for irrigation? |

|

| Is rainwater used for other purposes, e.g. toilet flushing ? |

|

| Does the building have a green roof / facade ? |

|

| Is reclaimed waste water used, e.g. from showers and sinks ? |

|

The quality of the indoor environment

| Is clean air supply automated ? |

|

| Is comfortable temperature during summer and winter automated? |

|

| Is natural lighting guaranteed in all living areas? |

|

| Is artificial lighting automated? |

|

| Is acoustic comfort, specifically reverberation time, guaranteed? |

|

| Does the layout solution include zoning and ergonomics elements? |

|

Principles of circular economics

| Does the project use recycled materials? |

|

| Does the project use recyclable materials? |

|

| Are materials with a documented Environmental Product Declaration (EPD) promoted in the project? |

|

| Are other sustainability certifications used for materials and elements? |

|

Energy efficiency

| Energy performance class of the building according to the Energy Performance Certificate of the building |

A

|

| Is efficient energy management (measurement and regular analysis of consumption data) considered? |

|

| Are renewable sources of energy used, e.g. solar system, photovoltaics? |

|

Interconnection with surroundings

| Does the project enable the easy use of public transport? |

|

| Does the project support the use of alternative modes of transport, e.g cycling, walking etc. ? |

|

| Is there access to recreational natural areas, e.g. parks, in the immediate vicinity of the building? |

|