| Author |

Jiří Stráský, Jiří Urban, Jan Nováček, Pavel Kolenčík |

| Studio |

Stráský, Hustý a partneři s.r.o. |

| Location |

Město Cheb, Kolejiště nádraží |

| Collaborating professions |

Mostní konstrukce |

| Investor |

Město Cheb, Náměstí krále Jiřího z Poděbrad 1/14, 350 20 Cheb, Václav Michálek, tel. 731 646 116, michalekv@cheb.cz |

| Supplier |

Swietelsky Rail s.r.o., U nákladového nádraží 3146/6 Praha 3 – Strašnice, Ing. Pavel Pechač; 725 762 591; p.pechac@swietelsky.cz |

| Date of completion / approval of the project |

September 2023 |

| Fotograf |

Miloš Vejchoda, m.vejchoda@shp.eu |

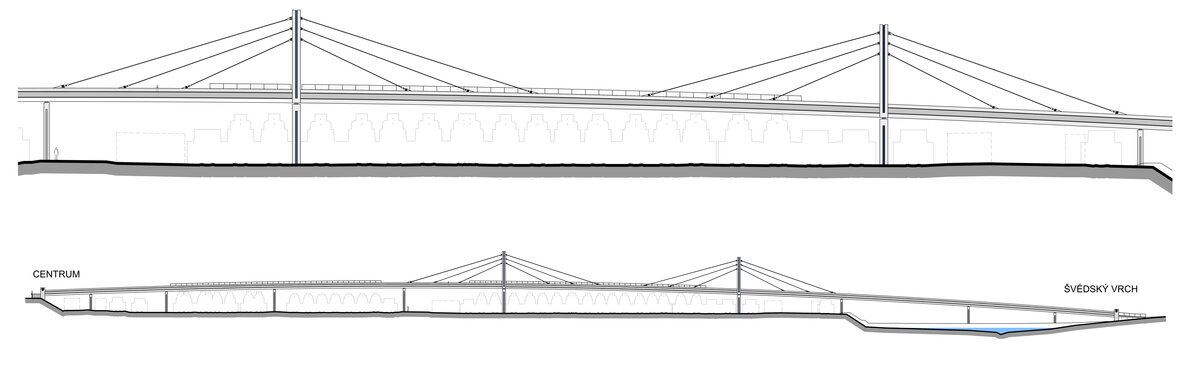

The footbridge replaces the original steel structure, which had to be demolished due to its poor technical condition. It is situated near the city’s center, south of the railway station. The footbridge crosses the railway infrastructure and connects the city center with its suburb parts Maškov and Švědský vrch. In order to ensure barrier-free access, the new footbridge is extended by approximately 100 m compared to the original structure and is connected to the adjacent area of the protective green screen.

The 398 m long footbridge crosses 6 local roads and in particular 39 rail tracks, which in most cases are electrified. On the city side, the structure is connected with local communications by a staircase and a ramp, on the Švédský vrch side by a ramp.

The existing position of the tracks and the new clearance requirements determined the position of supports. The main tracks require a span length of 87 m, the other tracks require span lengths from 37 to 48 m.

The city asked to design an economical structure of minimal maintenance which can be built with minimal restrictions on tracks traffic, which is comfortable for pedestrians and cyclists. It also required a concrete deck in view of a poor maintenance experience of the original steel structure.

Our effort was to design an efficient structure of a simple, clean shape, which will give a new dimension to the industrial environment of the railway yard. A structure that does not create a dominant feature, but which, with its clear and clean shape, expresses a static effect that allows to overcome a large span and which has the smallest possible structural depth.

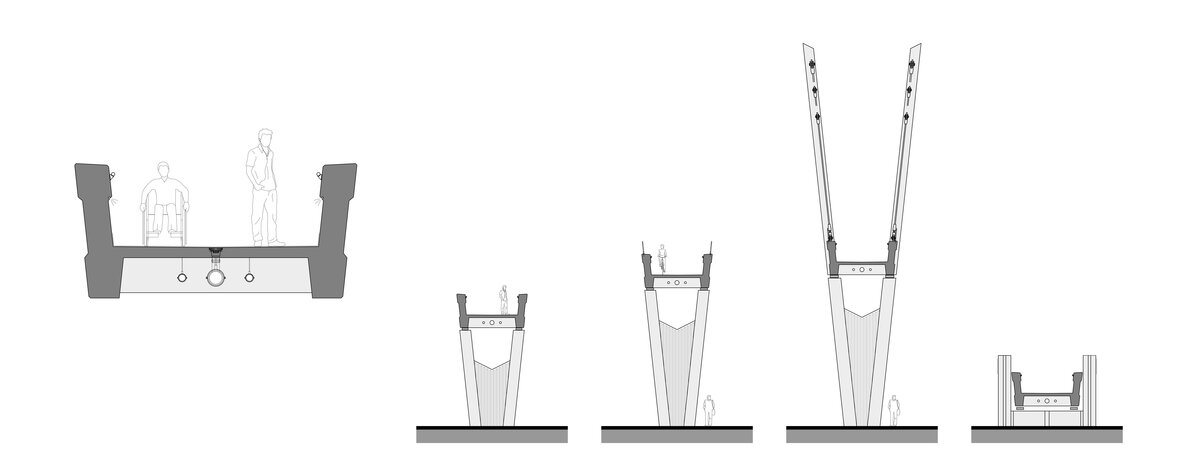

Therefore, a deck of a channel section of a constant depth of 2.00 m, which allows to safely bridge the length of 48 m was designed. In the main span the deck is suspended on two low pylons. All supports are formed by transversely inclined rectangular columns mutually connected by a central wall.

The deck and supports have a natural concrete colour. The lateral surface of the piers and the connecting walls are lightened by vertical grooves. The pylon and stay cables are light grey in colour, the side recesses in the pylon and in the piers are painted dark blue. The handrail consists of a circular pipe made of stainless steel. The footbridge is lit by LEED strips inserted into the upper flange of the parapet beam. Protection against touching the trolley consists of plexiglass with etched vertical stripes.

The 398 m long footbridge is formed by a continuous beam of 10 spans of lengths from 17.5 to 87.0 m. The bridge axis is straight in plan and it is in a crest elevation. The bridge consists of a 2.00 m deep channel beam, which is in the main span suspended on two 13.75 m tall pylons. The free width between the railings is 3.00 m. The edge beams are inclined outwards; their upper surface is at a height of 1.250 m above the deck slab. The edge beams have 60 mm deep recesses on both sides. The deck is drained by a central pipe situated under the slab where additional utility pipes are also located. The surface of the deck slab is protected by a walkable waterproof membrane.

With regard to the protection of the structure against stray currents, the bridge deck is dilated from the substructure which is supported by micropiles. Therefore, the bridge deck is supported by bearings. Internal supports are formed by transversely inclined rectangular columns mutually connected by central walls. The transversely inclined pylons optically follow the inclined piers’ columns. They are formed by steel columns of a box cross-section. The stay cables, which have a semi-radial arrangement, are from locked coil strands with Stylite Sockets connected to the steel plates protruding from the pylons and bridge deck.

The deck was incrementally concreted and then launched to the designed position. Static effects in launched structure were reduced by a steel nose and temporary supports. The casting plant was situated in the outermost span on the side of Švédský vrch. The footbridge was divided into 14 segments of 22-30 m length, which were incrementally prestressed by straight tendons coupled in joints between the segments. After the structure was launched, continuous tendons running along the entire length of the deck were pulled in and tensioned. Then the structure was placed on bearings, the temporary supports were removed, and finishing work and static and dynamic load tests were carried out.

Raeder & Falge, which was selected as the contractor in a tender, gradually constructed the bridge till the eighth segment. Unfortunately, in summer of 2022, the company went bankrupt and became insolvent. Fortunately, the investor managed to give the contract to Swietelsky Rail company in a very short time.

The construction of the footbridge was built with minimal traffic restrictions on the railway. Construction started in November 2020, it was put into operation in September 2023.

Green building

Environmental certification

| Type and level of certificate |

-

|

Water management

| Is rainwater used for irrigation? |

|

| Is rainwater used for other purposes, e.g. toilet flushing ? |

|

| Does the building have a green roof / facade ? |

|

| Is reclaimed waste water used, e.g. from showers and sinks ? |

|

The quality of the indoor environment

| Is clean air supply automated ? |

|

| Is comfortable temperature during summer and winter automated? |

|

| Is natural lighting guaranteed in all living areas? |

|

| Is artificial lighting automated? |

|

| Is acoustic comfort, specifically reverberation time, guaranteed? |

|

| Does the layout solution include zoning and ergonomics elements? |

|

Principles of circular economics

| Does the project use recycled materials? |

|

| Does the project use recyclable materials? |

|

| Are materials with a documented Environmental Product Declaration (EPD) promoted in the project? |

|

| Are other sustainability certifications used for materials and elements? |

|

Energy efficiency

| Energy performance class of the building according to the Energy Performance Certificate of the building |

|

| Is efficient energy management (measurement and regular analysis of consumption data) considered? |

|

| Are renewable sources of energy used, e.g. solar system, photovoltaics? |

|

Interconnection with surroundings

| Does the project enable the easy use of public transport? |

|

| Does the project support the use of alternative modes of transport, e.g cycling, walking etc. ? |

|

| Is there access to recreational natural areas, e.g. parks, in the immediate vicinity of the building? |

|