| Author |

Martin Prokš, Marek Přikryl |

| Studio |

Prokš Přikryl architekti |

| Location |

Automatické mlýny 1963, 530 03 Pardubice |

| Collaborating professions |

Betonové konstrukce: MDS PROJEKT, Ocelové konstrukce: STA-CON, PBŘ: PROJEKTY PO, ZTI: MK Profi, Větrání: MIKROKLIMA, Vytápění: Jiří Vik, Elektro: Miroslav Bouček, Akustika, A/V média: SONING, Osvětlení: Ladislav Tikovský, MaR: TECONT |

| Investor |

Nadace Automatické mlýny, Lukáš Smetana, Mariana Smetanová |

| Supplier |

STAKO Hradec Králové |

| Date of completion / approval of the project |

September 2023 |

| Fotograf |

Petr Polák |

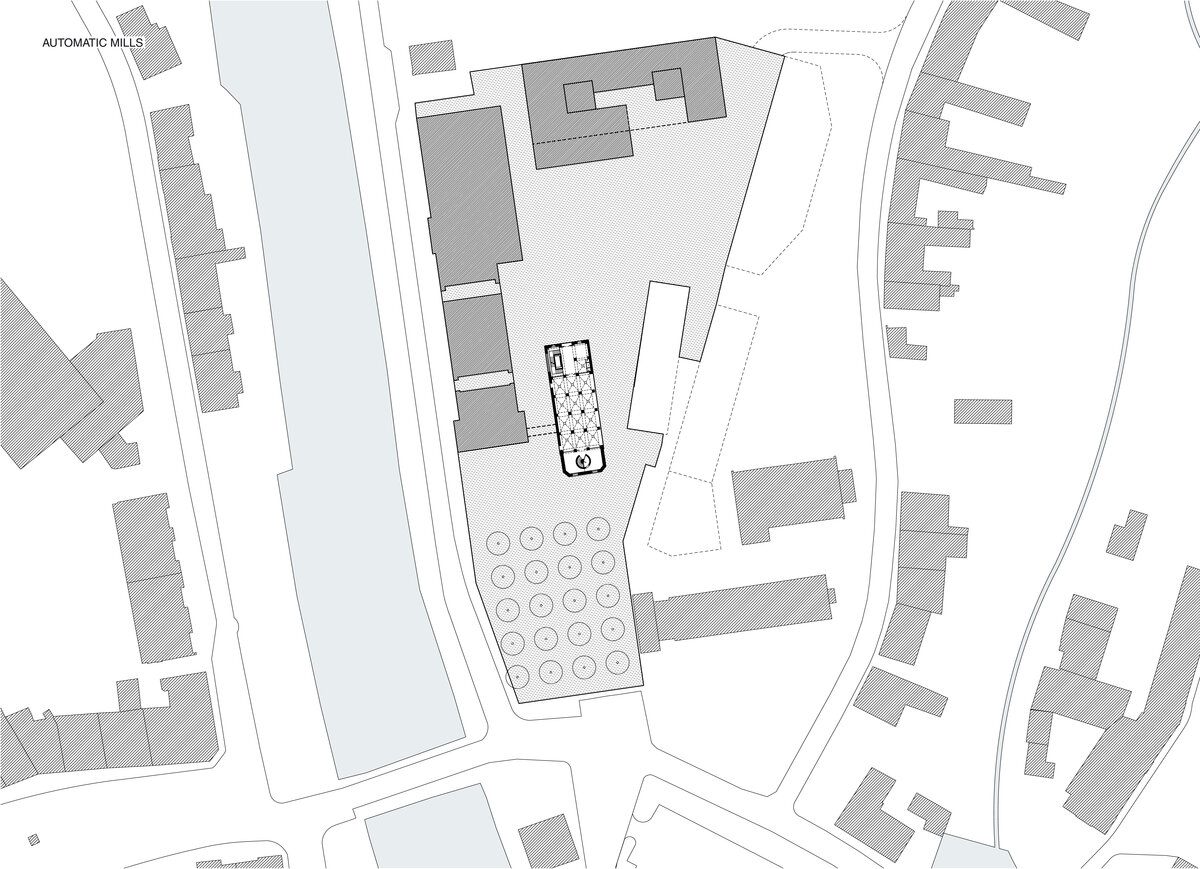

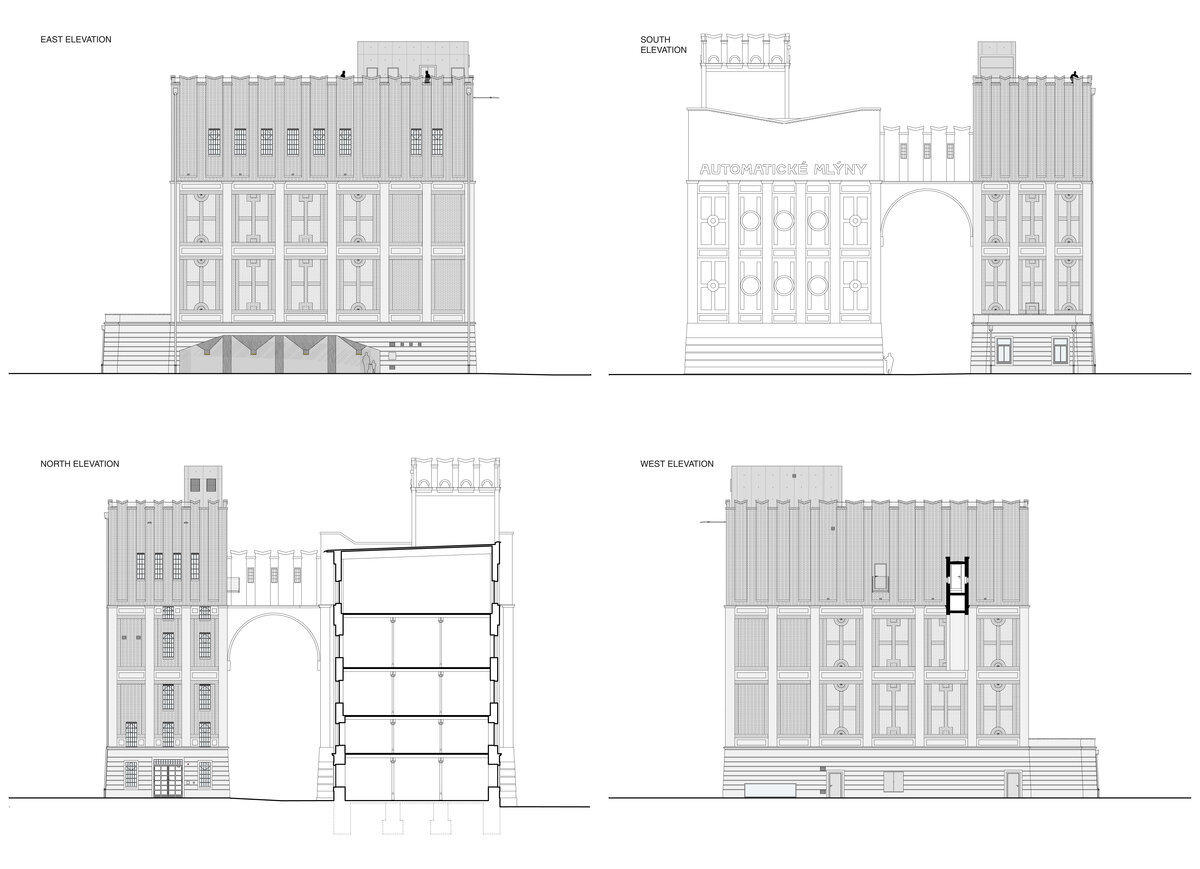

The Automatic Mills, a national cultural monument, is one of the first buildings designed by Josef Gočár, who was to become one of the greatest Czech architect of the 20th century. Standing on the banks of the Chrudimka River in the centre of Pardubice, the monumental mill building was created in 1909. In 1924, the complex was extended to include a grain silo, the conversion of which we designed. The automatic mills operated continuously for more than 100 years until 2013. Since 2016, the mill brownfield has been undergoing transformation into a cultural and social urban district

The site is composed of several buildings and institutions (the regional Gočár Gallery, the city's “Gampa” Gallery, the “Sphere” central school workshops, the Infocentre and the Silo), linked by a brick carpet and equally by the unique tension existing between them. Each of the architects has grasped their building in a different way. All the buildings reinforce each other and thus form a living part of the city. The exceptional architects Zdeněk Balík, Jan Šépka, Petr Všetečka and investor Lukáš Smetana have contributed to the whole.

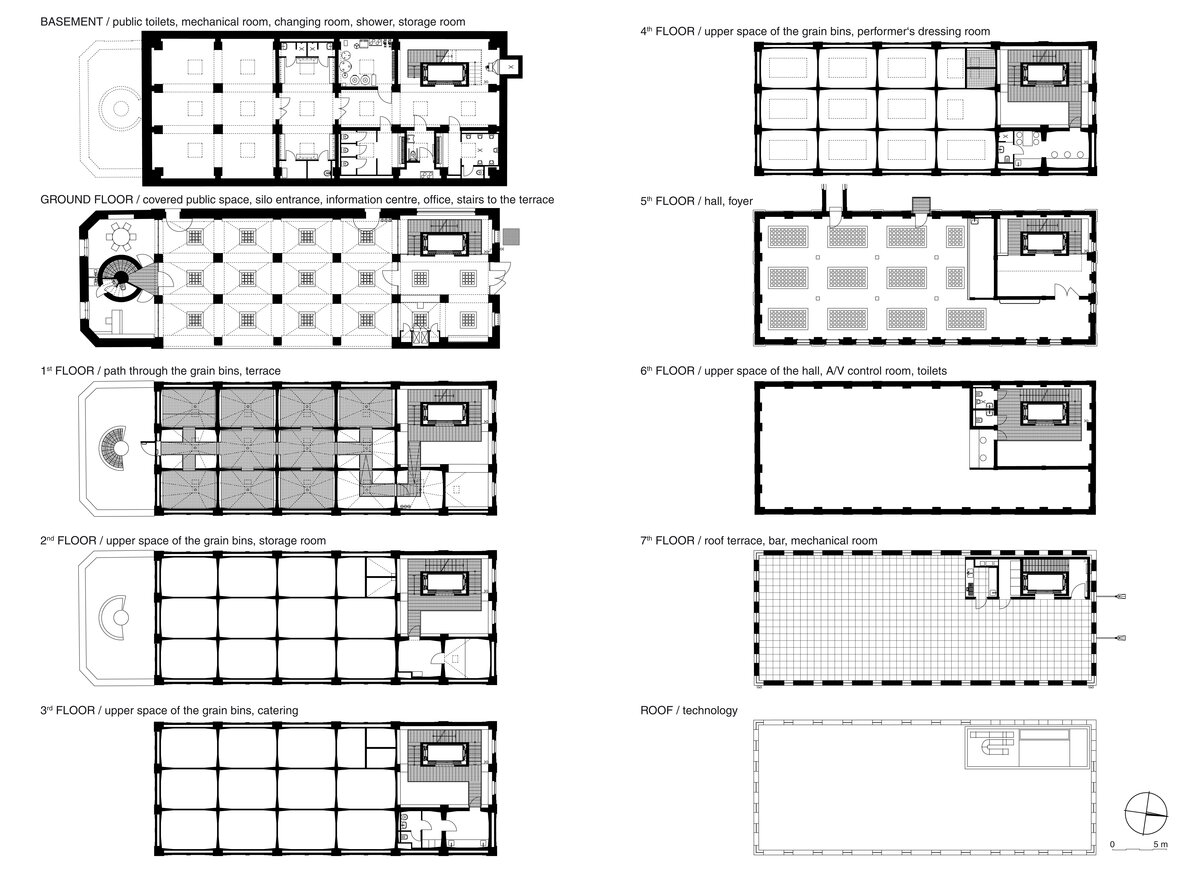

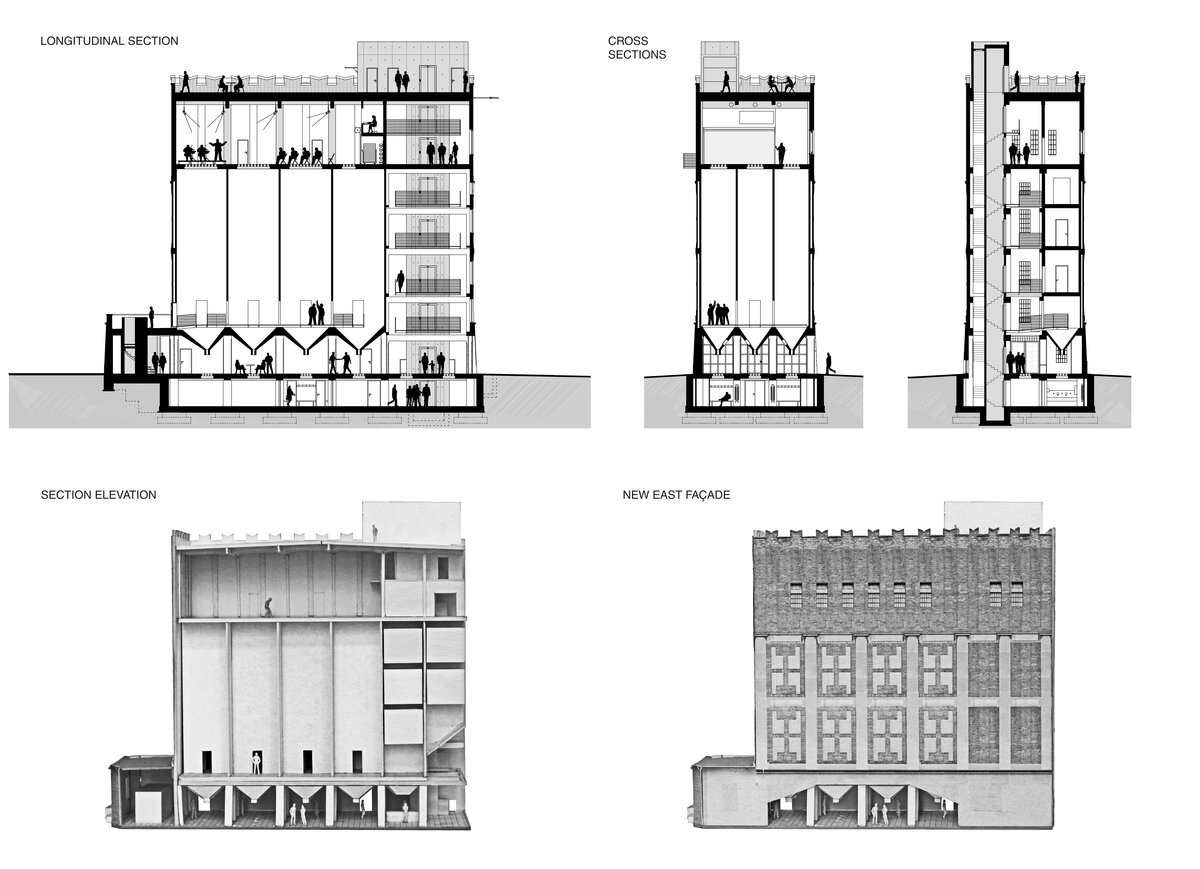

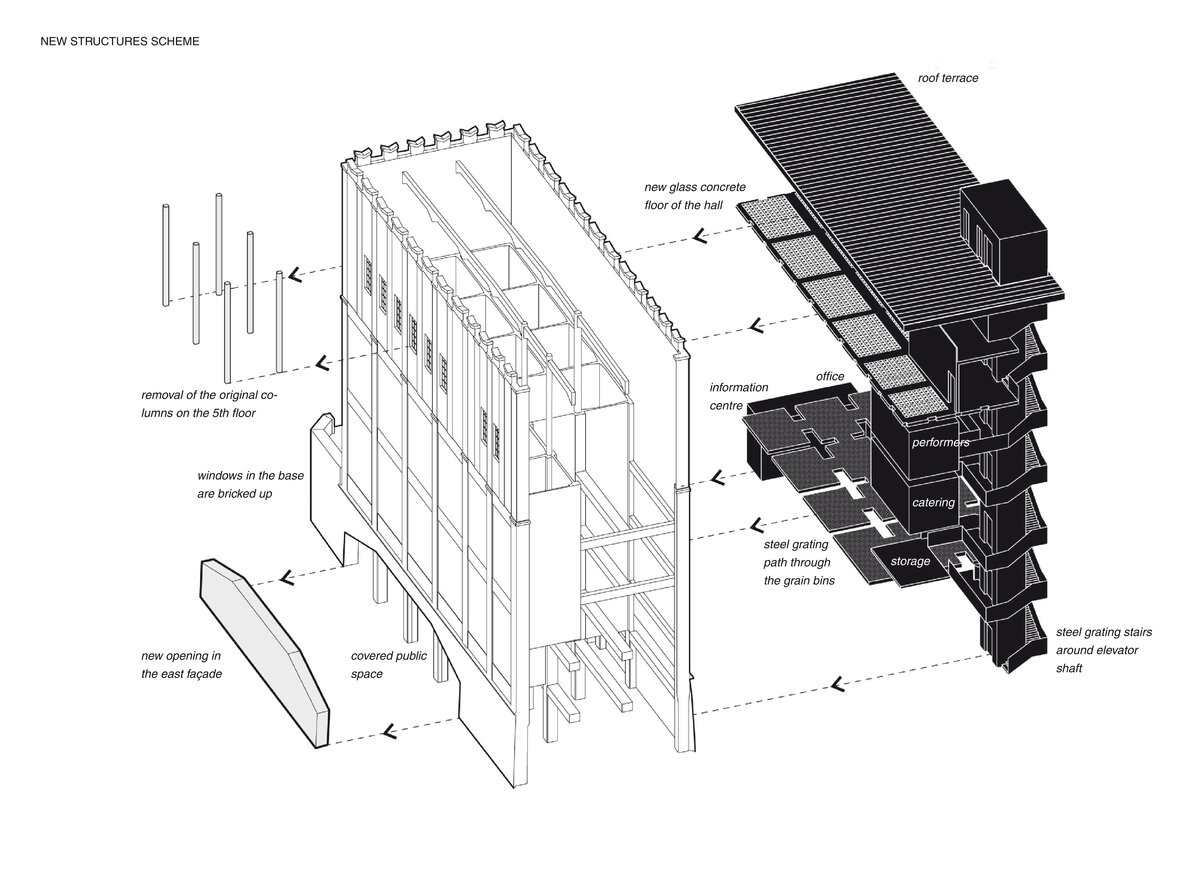

The main purpose of the Silo conversion is its social use, which one century after its construction has replaced the previous industrial function. The multi-purpose upper hall hosts theatres, lectures, concerts and social events. The roof terrace with bar offers a new view of the city. Exhibitions will be held in the newly accessible grain bins. Here, the very essence of the silo becomes visible. The silo ground floor now forms a covered public space and a basement, almost an underworld of their own, with public toilets provides facilities for the new square.

The idea of opening the building to the square went hand in hand with the overall opening of the site to the city. Opening the gates, opening the parterre. The base, that had been mysteriously closed, is now broken through by a wide new opening.

Today, as in the past, a single communication core connects the whole. The main change is the hall inserted into the former machine room on the 5th floor. Together with the hall, the roof has been made wheelchair accessible.

Colours and brickworks are confined to the facades, the interior is muted, the range of materials is standard. All original surfaces are retained, including the patinas, or various drill holes and scars left by the demolished partition walls. Simply put, the aim is to develop the building in its rationality and monumentality.

The construction interventions involved mainly creating a full-length basement for the building, insertion of a communication core and construction of an open hall space in place of the pillared hall on the 5th floor. The condition of the 100-year-old concrete, which is now approximately C16/20, was very good, showed no defects and no repair was necessary. However, the horizontal structures did not meet the required loads and therefore were all replaced with new ones.

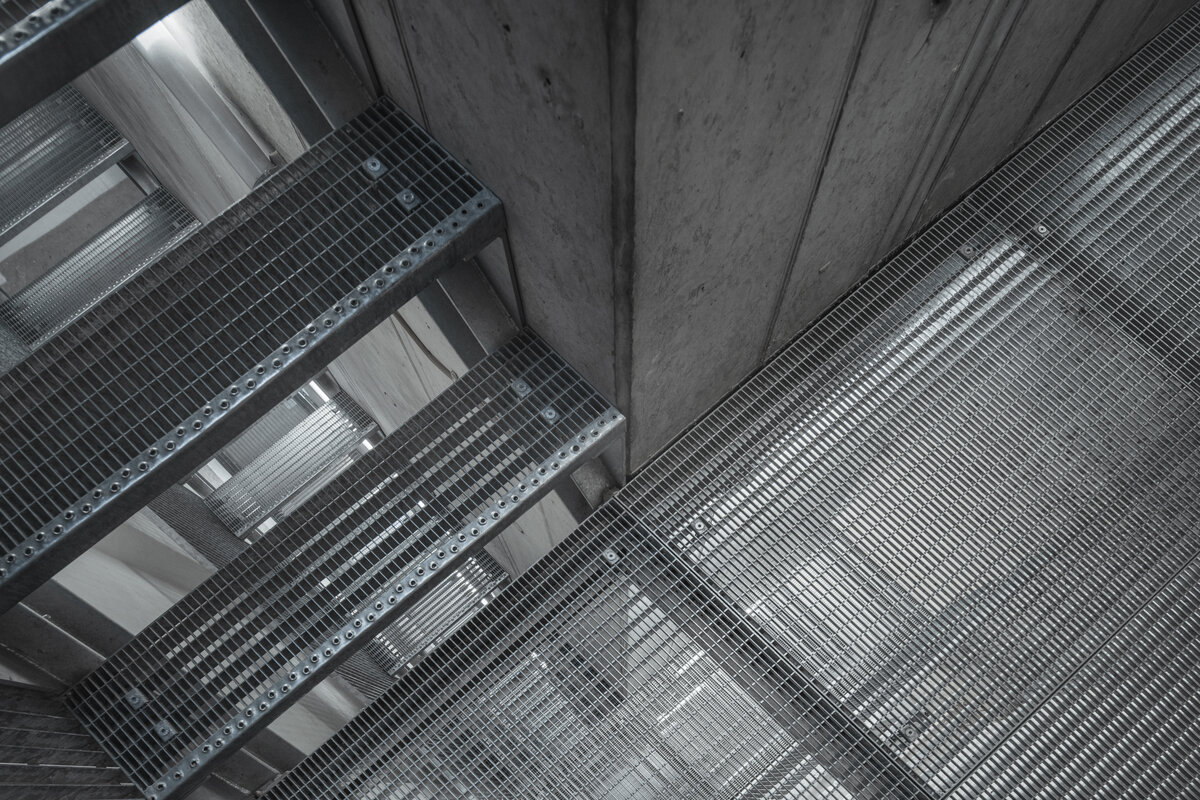

The basement, due to the groundwater level, was constructed as a white tank of waterproof exposed concrete with walls 300 mm thick. The entire structure was placed atop the existing footings and coupled with the columns. Upthrust risk was verified by calculation. An elevator shaft was concreted between the skeleton beams running the full height of the building. Surrounding this shaft is a steel grating staircase, anchored to the shaft walls via the stringers. A specific situation was the cutting of door-sized holes (920/2250 mm) in the monolithic walls of the grain bins.

For the new hall in the 5th floor, the ceiling, columns, roof slab and attic were removed. Of the original structure, only the perimeter brickwork remained.New C-shaped columns were concreted to the existing columns in the perimeter masonry. A new flat roof was built, the attic was bricked in, and the shaft was finished off with a roof extension made of exposed concrete.

The defining point of fire safety was the hall at the level of the 5th floor and the roof terrace, from which there is only one escape route. The stairwell is a protected Type B escape route with forced ventilation, with the exhaust in the roof extension. The precast glass-concrete floor panels on the ground floor and in the hall have a fire resistance of up to 90 minutes.

The building is partially heated. Due to the listed facades, the above-ground heated spaces are insulated internally. Calcium-silicate slabs of 75 mm thickness were used, as they place no burden on the existing structures in terms of year-round water vapour balance. The building is heated by a ground-to-water heat pump, where the heat source consists of six geothermal boreholes 120 m deep at the front of the site. The ventilation system is decentralised, equipped with heat recovery, while the main unit for ventilating the hall is located on the roof of the roof extension on the 8th floor. All heating, ventilation and lighting systems are connected to remote control and monitoring.

Green building

Environmental certification

| Type and level of certificate |

-

|

Water management

| Is rainwater used for irrigation? |

|

| Is rainwater used for other purposes, e.g. toilet flushing ? |

|

| Does the building have a green roof / facade ? |

|

| Is reclaimed waste water used, e.g. from showers and sinks ? |

|

The quality of the indoor environment

| Is clean air supply automated ? |

|

| Is comfortable temperature during summer and winter automated? |

|

| Is natural lighting guaranteed in all living areas? |

|

| Is artificial lighting automated? |

|

| Is acoustic comfort, specifically reverberation time, guaranteed? |

|

| Does the layout solution include zoning and ergonomics elements? |

|

Principles of circular economics

| Does the project use recycled materials? |

|

| Does the project use recyclable materials? |

|

| Are materials with a documented Environmental Product Declaration (EPD) promoted in the project? |

|

| Are other sustainability certifications used for materials and elements? |

|

Energy efficiency

| Energy performance class of the building according to the Energy Performance Certificate of the building |

|

| Is efficient energy management (measurement and regular analysis of consumption data) considered? |

|

| Are renewable sources of energy used, e.g. solar system, photovoltaics? |

|

Interconnection with surroundings

| Does the project enable the easy use of public transport? |

|

| Does the project support the use of alternative modes of transport, e.g cycling, walking etc. ? |

|

| Is there access to recreational natural areas, e.g. parks, in the immediate vicinity of the building? |

|